Reducing Downtime and Increasing Uptime with Modern Mine Machinery

In the mining industry, operational efficiency is crucial for maximizing productivity and profitability. Modern mine machinery plays a vital role in achieving this efficiency, particularly through the reduction of downtime and the enhancement of uptime. As mining operations become increasingly complex and demanding, the integration of advanced machinery and technology has become essential in addressing these challenges. Downtime refers to periods when machinery is not operational due to maintenance, repairs, or malfunctions. It represents a significant loss in productivity and can have a cascading effect on the entire mining operation. Conversely, uptime refers to the amount of time that machinery is operational and productive. The goal is to maximize uptime and minimize downtime to ensure continuous and efficient mining processes. Modern mine machinery is designed with advanced features and technologies that enhance reliability, performance, and efficiency. Here are some key aspects in which modern machinery contributes to reducing downtime and increasing uptime:

Predictive Maintenance

Predictive maintenance is a proactive approach enabled by modern machinery. Through the use of sensors, IoT devices, and data analytics, machinery can continuously monitor its condition and performance. This real-time data allows for the early detection of potential issues before they escalate into major problems. By predicting when a component is likely to fail, maintenance can be scheduled in advance, reducing unexpected breakdowns and extending the machinery’s lifespan.

Automated Diagnostics

Automated diagnostic systems are integral to modern mining equipment. These systems can quickly identify and diagnose faults or malfunctions in machinery, reducing the time required for manual troubleshooting and visit this site www.jxscmachine.com/fr/. Automated diagnostics not only speed up the repair process but also ensure that issues are addressed accurately, minimizing the risk of recurring problems.

Advanced Training and Simulation

Modern mine machinery often comes with sophisticated training and simulation systems. These systems help operators familiarize themselves with the machinery’s functions and handling without the risk of damaging actual equipment. Well-trained operators are more likely to use machinery efficiently and avoid operational mistakes that could lead to downtime.

Enhanced Durability and Reliability

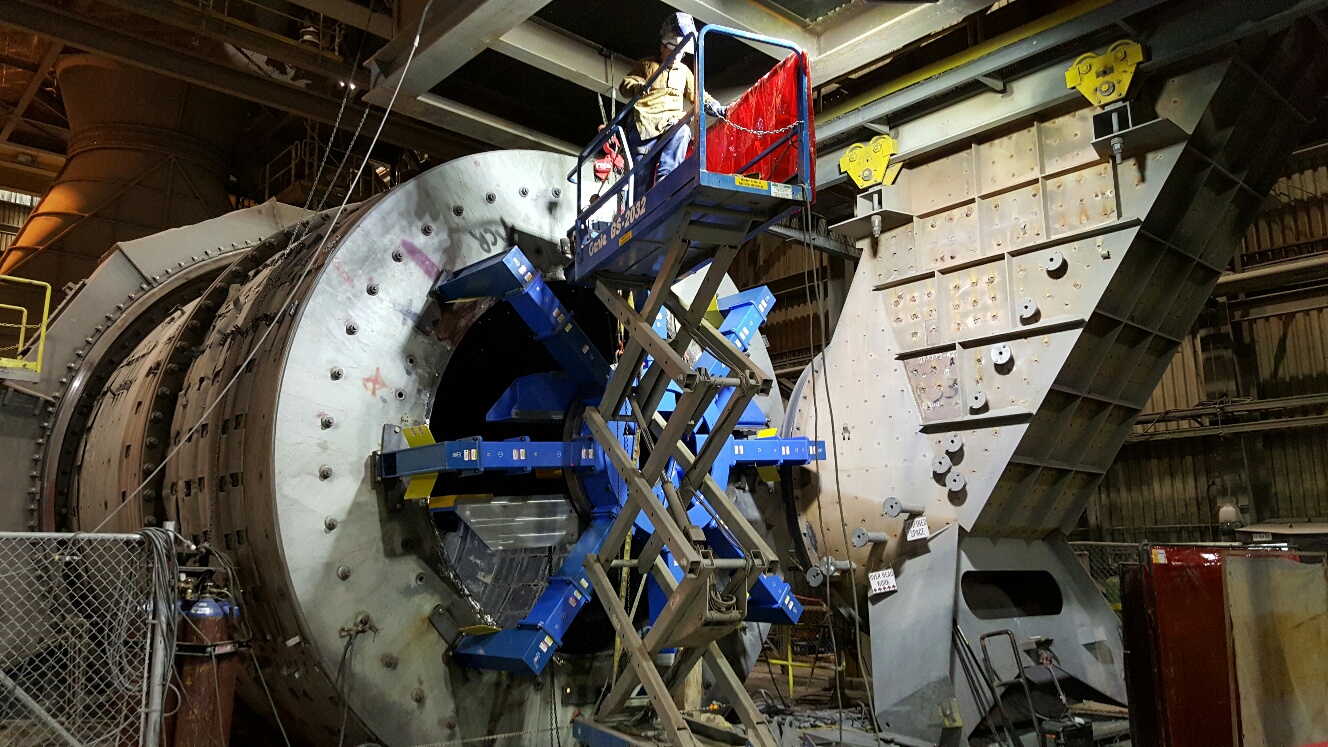

Advances in materials and engineering have led to the development of more durable and reliable mining machinery. Components are designed to withstand harsh mining environments, reducing the frequency of repairs and replacements. For instance, high-strength alloys and wear-resistant coatings can significantly extend the life of critical components.

Efficient Spare Parts Management

Efficient management of spare parts is another crucial factor in reducing downtime. JXSCMachine factory often includes systems for tracking and managing spare parts inventory. By ensuring that critical components are readily available, mining operations can avoid prolonged downtimes due to waiting for parts.

Reducing downtime and increasing uptime in mining operations hinges on the integration of modern machinery equipped with advanced technologies. Predictive maintenance, automated diagnostics, enhanced training, durability, remote monitoring, and efficient spare parts management are all integral to maximizing operational efficiency. As the mining industry continues to evolve, embracing these technological advancements will be key to maintaining competitive edge and achieving long-term success.